PCO vs HEPA: The Complete Guide to Air Purification Technologies

Share

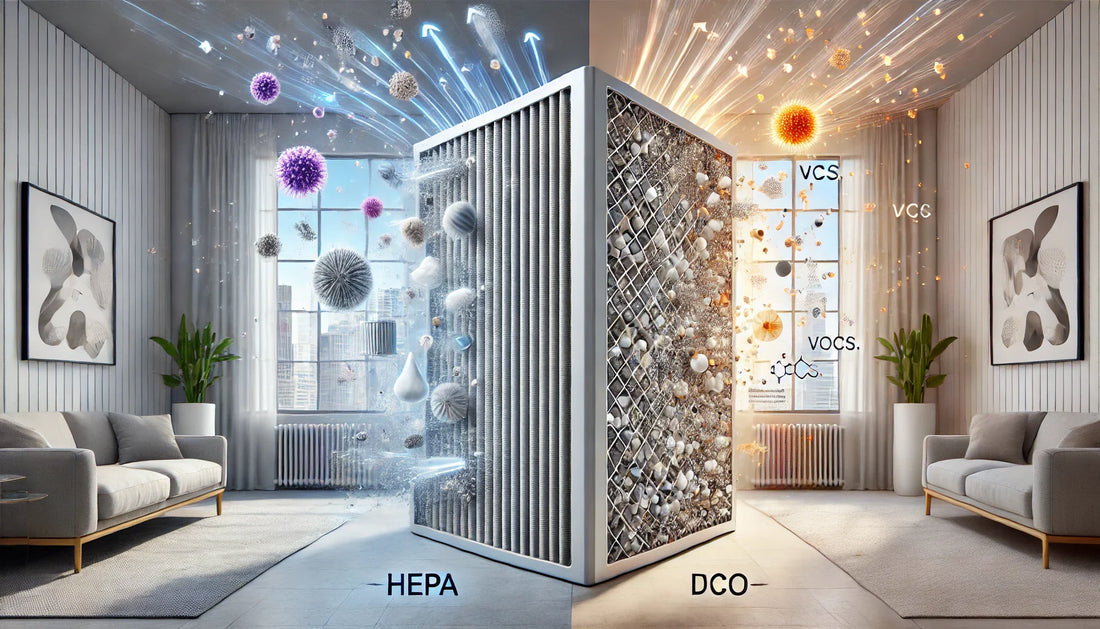

The air purification industry has evolved significantly from basic mechanical filtration to advanced molecular-level cleaning technologies. Understanding the differences between High-Efficiency Particulate Air (HEPA) filters and Photocatalytic Oxidation (PCO) systems helps consumers make informed decisions about their indoor air quality needs.

Understanding HEPA Filter Technology

HEPA filters, developed during World War II for military applications, work through mechanical filtration. These dense fiber mats trap 99.97% of particles 0.3 microns or larger, effectively capturing dust, pollen, pet dander, and some bacteria. The technology relies on airflow passing through the filter media, where particles become physically trapped.

While effective for particulate matter, HEPA filters have limitations. They cannot eliminate gases, odors, or volatile organic compounds (VOCs). Additionally, trapped particles remain alive within the filter, potentially creating breeding grounds for bacteria and mold if not replaced regularly. The physical nature of HEPA filtration also restricts airflow, requiring powerful fans that consume more energy and generate noise.

The Science Behind Photocatalytic Oxidation

Photocatalytic oxidation technology mimics nature's own air cleaning process. Originally developed by NASA for space missions, PCO uses ultraviolet light combined with a photocatalyst (typically titanium dioxide) to create hydroxyl radicals and superoxide ions. These powerful yet safe oxidizers break down contaminants at the molecular level.

Unlike mechanical filtration, PCO doesn't trap pollutants – it destroys them. Bacteria, viruses, mold spores, VOCs, and odor-causing molecules are converted into harmless water vapor and carbon dioxide. This process occurs continuously in the air, providing proactive purification rather than passive filtering.

Performance Comparison: Effectiveness and Scope

HEPA filters excel at removing visible particles but struggle with smaller contaminants and gases. A typical HEPA system captures particles down to 0.3 microns, missing many bacteria (0.1-0.2 microns) and all molecular-level pollutants like VOCs and odors.

PCO technology addresses this gap by working at the molecular level. It effectively eliminates particles of all sizes plus gases, chemicals, and biological contaminants that pass through HEPA filters. This comprehensive approach provides more complete air purification, addressing both particulate and gaseous pollutants simultaneously.

Maintenance and Operational Differences

Traditional HEPA systems require regular filter replacement every 6-12 months, depending on usage and air quality. Filter costs range from $30-100+ annually, and performance degrades steadily as filters become clogged. Users must monitor filter life and maintain replacement schedules to ensure continued effectiveness.

PCO systems operate without replaceable filters, eliminating maintenance requirements and ongoing costs. The photocatalyst remains active throughout the unit's lifetime, providing consistent performance without degradation. This maintenance-free operation offers significant convenience and cost advantages over traditional systems.

Size, Portability, and Power Considerations

HEPA air purifiers require substantial size to accommodate large filter surfaces and powerful fans needed to push air through dense media. This results in bulky units that consume significant power and generate noise during operation. Most HEPA systems are designed for stationary use in single rooms.

PCO technology enables compact, portable designs that traditional systems cannot achieve. Without bulky filters, PCO units like the LUFT series can be handheld, USB-powered, and easily transported between locations. This portability makes them ideal for travel, office use, cars, and any situation where traditional air purifiers aren't practical.

Environmental Impact and Sustainability

HEPA systems generate ongoing waste through regular filter disposal. Used filters contain trapped contaminants and typically end up in landfills, creating environmental concerns. The manufacturing and shipping of replacement filters also contribute to the carbon footprint of traditional air purification.

PCO technology offers a more sustainable approach through filter-free operation. Without replacement parts, these systems generate no ongoing waste and have a lower lifetime environmental impact. The energy efficiency of compact PCO units further reduces their ecological footprint.

Choosing the Right Technology for Your Needs

The choice between HEPA and PCO depends on specific requirements and priorities. HEPA filters work well for basic particulate removal in stationary applications where ongoing maintenance isn't a concern. However, for comprehensive air purification, portability, cost-effectiveness, and convenience, PCO technology offers significant advantages.

Modern PCO systems like the LUFT collection combine advanced air purification with practical benefits that traditional HEPA systems cannot match. For consumers seeking the most advanced, convenient, and cost-effective air cleaning solution, photocatalytic oxidation represents the future of air purification technology.